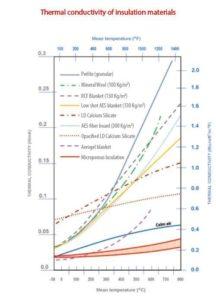

Mineral wool remains the most widely used insulation material in Poland. However, it is worth to remember about alternative and less common materials. According to Turner and Malloy classification from 1981 there are 5 main categories of insulation materials: cellular, fibrous, flake, granular and reflective. For an instance, an insulation made of cellular material with an open cell structure is capable of transferring gases, which makes it a perfect choice for the industrial facilities where such properties are required. Reflective Insulations and treatments are added to surfaces to lower the long-wave emittance thereby reducing the radiant heat transfer to or from the surface. Polyurethane poured industrial insulation is a foam of a closed cell structure with use temperature between -30°C and 107°C and compressive strength reaching 400 kPa, one may apply it to elements, hardly reachable using conventional insulation methods. Polyimide insulation has open cell structure, is applied in a traditional way, its’ use temperature ranges from -200°C to 300°C with a phenomenal density of 8 kg/m3. (density of mineral wool – 80 kg/m3) Insulation materials are further categorised with regard to their technical, physical and chemical parameters, such as use temperature, thermal conductivity, thermal resistance, nominal density, specific heat, thermal diffusivity, alkalinity (pH level), compression and flexural resistance, linear shrinkage, water vapour permeability, water absorption, water vapour sorption and wicking. A thorough analysis of operational factors for the element as well as for the entire facility allows us to choose the best insulation material in terms of saving, effectiveness, safety and durability. A general comparison of main characteristics presented for other insulation materials.